جودة

التزامنا بالتميز في جودة الإغلاق

مادة

المواد الخام التي نستخدمها حاصلة على شهادة الاتحاد الأوروبي ويمكن تتبعها, آمنة للاستخدام في الصناعة, أُسرَة, العناية بالسيارات وصناعات الهباء الجوي. كما أننا نستخدم المواد البلاستيكية المخصصة للطعام&محلول إغلاق المشروبات.

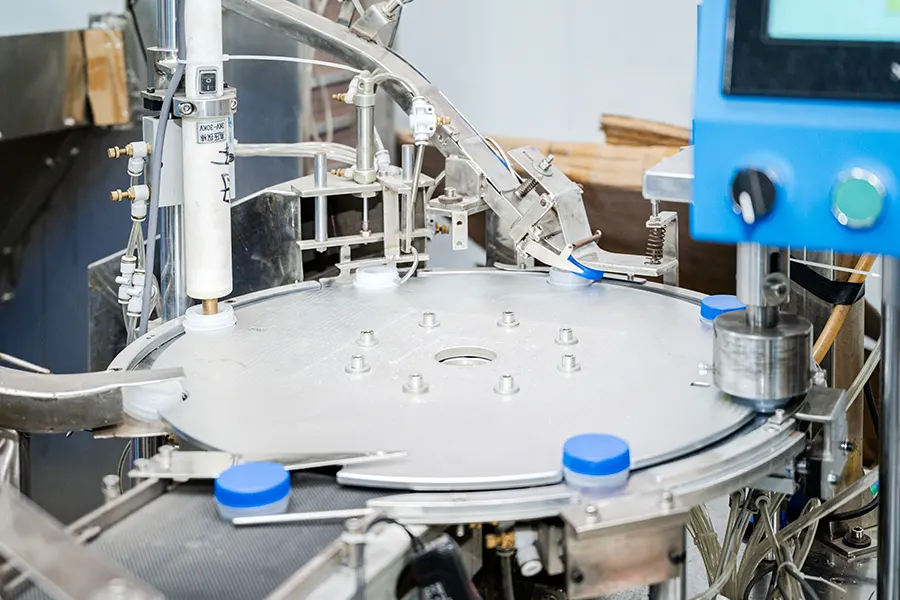

تصنيع

مجهزة بإنتاج أوتوماتيكي كامل, آلات التجميع والفحص البصري في مصانعنا, يتم اختبار كل غطاء بشكل مستمر وكامل للتأكد من الجودة في النظام.

موافقة & الشركة المصنعة للإغلاق المعتمد

الجودة الفائقة تكمن في الحرفية الفائقة

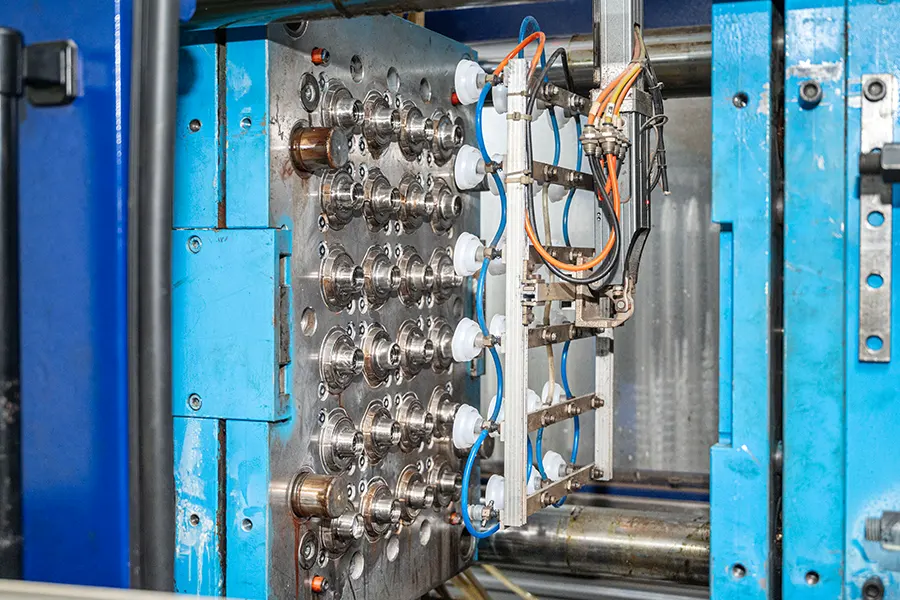

المعدات الحديثة

توفر أحدث آلات القولبة بالحقن الهايتية في منشأتنا دقة استثنائية.

القوى العاملة الماهرة

يفتخر فريق الإنتاج لدينا بقدامى المحاربين في الصناعة 10 سنوات من الخبرة في صب, التصميم والإنتاج.

رقابة صارمة على الجودة

نقوم بإجراء اختبارات العينات كل ساعة, من فحص المواد الخام إلى التغليف النهائي.

التحسين المستمر

من خلال نظام إدارة الجودة 5S الخاص بنا, نحن نعمل باستمرار على تحسين بيئة الإنتاج.

نحن لا نفي بالمعايير فحسب, نحن نتفوق عليهم

ختم ممتاز لإثبات التسرب

يتم اختبار كل دفعة من عمليات الإغلاق من أجل الختم عن طريق الفحص البصري الآلي بالكامل واختبار ضغط الماء للتأكد من الامتثال لمتطلباتك الخاصة بمنع التسرب. لا مفاجآت, لا توجد اختلافات.

سلامة أكبر من خلال مقاومة الصدمات

ال 1.5 أثبت اختبار سقوط العداد أن إغلاقنا ظل سليمًا وغير مشوه بعد الاصطدام, وبالتالي ضمان التخزين الآمن للمحتويات وطمأنة المستخدمين. منتجاتك تبقى آمنة, يؤمن, وطازجة, بناء الثقة مع المستخدمين النهائيين لديك.

إدارة الجودة المتميزة ضد التآكل

لتحقيق حماية متسقة من التآكل, نحن بحاجة للذهاب إلى أبعد من ذلك. إن الحصول على المواد الخام عالية الجودة في الصناعة فقط والاستفادة من ورشة العمل الخالية من الغبار للتحكم في البكتيريا المحتملة والتلوث يؤدي إلى نظافة, عمليات إغلاق مرنة تصمد أمام التعرض البيئي.

تحدي تحدي درجات الحرارة المرتفعة

يتم اختبار القبعات في كل دفعة في 50 درجات لميزات مثل النزاهة, الإطار الزمني للسلامة والتخزين. وهذا يسمح لإغلاقنا بضمان الجودة الممتازة من الوحدة الأولى إلى الوحدة الأخيرة من المنتج. سواء كنت تبحث عن حل إغلاق متخصص أو عالمي, لا يمكنك أن تخطئ أبدًا.