An industrial plastic cap is a functional closure used in chemical and industrial packaging. It can be threaded, snap-on, or tamper-evident, designed to secure containers, organize handling, prevent spillage during transport, and serve as a masking element during processes like coating or labeling. Different types of plastic caps are manufactured using specific molding processes, which determine their strength, precision, and usability.

In the following sections, we will explore the main molding methods used in plastic cap production and how each affects performance and application.

What Is the Molding Process in Manufacturing?

Molding is a manufacturing method that shapes raw plastic material into a predefined form using a mold. It combines heat, pressure, and sometimes chemical reactions to make the plastic conform to the mold cavity. Unlike casting, where liquid material simply hardens in a mold, or forming, which reshapes material mechanically, molding ensures precise dimensions, consistent quality, and the ability to produce complex shapes.

The molding process also influences the mechanical properties of the cap, such as rigidity, flexibility, and durability. For high-volume production, molding methods that allow rapid cycles and uniform quality are preferred.

Overview of the Most Common Different Types of Molding Process

Plastic cap manufacturing relies on four major molding processes: injection molding, compression molding, blow molding, and two-shot or multi-shot molding.

- Injection Molding is the most common, suitable for high-volume, precision applications.

- Compression Molding works well for thicker or specialized material caps.

- Blow Molding is ideal for hollow or bottle-top caps.

- Two-Shot and Multi-Shot Molding allows combining multiple materials or colors in a single part.

| Molding Process | Description | Key Features | Limitations | Cost Level | Typical Applications |

| Injection Molding | Molten plastic injected into steel mold under high pressure. | High precision (±0.05 mm); fast cycle times; complex designs possible. | High initial mold cost; less suited for thick/hollow parts. | High tooling cost, low per-unit cost at scale. | Screw caps, spout caps, child-resistant caps, tamper-evident closures, beverage bottle caps. |

| Compression Molding | Pre-measured plastic pressed in heated mold cavity. | Strong, dense parts; good heat and chemical resistance; works with thermosets. | Slower cycles; limited design complexity; less smooth finish. | Moderate tooling, slower production. | Heavy-duty industrial caps, oil/lubricant/solvent container closures. |

| Blow Molding | Heated plastic tube (parison) inflated inside mold to form hollow shapes. | Efficient for hollow caps; can integrate spouts/hinges; tolerances ±0.2 mm. | Lower precision; weaker strength; limited to simpler designs. | Lower tooling cost, cost-effective for volume. | Spout caps, sports drink closures, dispensing caps. |

| Two-Shot / Multi-Shot Molding | Two or more plastics injected sequentially into one mold. | Combines rigid + soft materials; multi-color/texture; precise bonding. | High equipment cost; longer cycles; complex setup. | Very high initial investment. | Premium cosmetic caps, pharma closures with seals, multi-color or soft-grip caps. |

Injection Molding

Injection molding is a precise manufacturing process in which plastic pellets are heated until molten and injected into a steel mold under high pressure. The molten plastic fills the mold cavity, taking the exact shape of the cap design. Once cooled, the mold opens, and the finished cap is ejected. This process works well with thermoplastics such as polypropylene (PP), polyethylene (PE), and polystyrene (PS), which offer good flow characteristics, durability, and resistance to cracking. It is particularly suitable for high-volume production due to fast cycle times and consistent quality.

Injection molding is ideal for producing screw caps, spout caps, child-resistant caps, tamper-evident closures, and standard beverage bottle caps. The method allows detailed features such as internal ribs to increase structural strength without adding extra material. Tolerances can be as tight as ±0.05 mm, ensuring caps fit bottles accurately and perform reliably in sealing applications.

| Advantages | Disadvantages |

| High precision and tight tolerances (±0.05 mm) | High initial mold cost ($5,000–$50,000) |

| Fast production suitable for high-volume runs | Less suitable for very thick or hollow caps |

| Ability to produce complex designs and detailed features | Requires careful material and temperature control |

| Consistent quality and repeatability | Limited flexibility for multi-material or color designs |

Compression Molding

Compression molding involves placing a pre-measured amount of plastic into an open, heated mold cavity. The mold is then closed, and pressure forces the plastic to conform to the cavity shape. After cooling, the cap is removed. This method works particularly well with thermoset plastics like phenolic or melamine, which are difficult to process using injection molding.

Compression molding is ideal for producing thick, heavy-duty caps for industrial and chemical containers, such as oil, lubricant, and solvent bottle closures, where durability and resistance to heat, chemicals, and impact are essential. Tolerances are typically around ±0.1 mm, slightly larger than injection molding but sufficient for industrial use. It is also compatible with simpler cap designs that do not require highly detailed threads or intricate logos.

| Advantages | Disadvantages |

| Produces thick, strong, and durable caps | Slower cycle times than injection molding |

| Suitable for thermoset plastics and high-temperature applications | Limited design complexity and surface detail |

| Excellent chemical and heat resistance | Lower production volumes |

| Reliable performance for industrial applications | Requires precise material measurement and pressing |

Blow Molding

Blow molding is a manufacturing process in which heated plastic is inflated with air inside a mold cavity to form hollow shapes. The process begins with a parison or preform (a heated tube of plastic) being placed into the mold. Compressed air is then introduced, expanding the plastic against the mold walls to create the desired shape. Once cooled, the mold opens, and the finished product is removed. This technique works especially well with polyethylene (PE) and polyethylene terephthalate (PET).

Blow molding is primarily used for manufacturing hollow plastic items such as bottles, jars, and containers, including caps with integral spouts or hinged closures. While the process allows for functional designs, it is less precise than injection molding. Typical tolerances are around ±0.2 mm, which is sufficient for non-threaded caps or simple dispensing features but less suitable for high-precision closures.

| Advantages | Disadvantages |

| Efficient for hollow or lightweight cap designs | Lower precision compared to injection molding |

| Cost-effective for large bottles and containers | Limited to simpler cap geometries |

| Relatively low tooling cost | Surface details and threads are less accurate |

| Can produce integrated spouts or hinged parts | Weaker structural strength than injection/compression molding |

Two-Shot and Multi-Shot Molding

Two-shot (or multi-shot) molding is an advanced process in which two or more different plastics are injected into the same mold in sequential steps, creating a single integrated part. This method enables the combination of different colors, textures, or material properties in one cap. For example, a rigid polypropylene body can be molded together with a soft thermoplastic elastomer (TPE) liner to improve grip and sealing.

This technique is commonly used in premium packaging, pharmaceuticals, and personal care products where both functionality and visual appeal are important. Caps with soft-touch grips, multi-color branding, or built-in seals are often made using two-shot molding. Tolerances are typically similar to standard injection molding, around ±0.05–0.08 mm, ensuring reliable sealing performance while enabling complex designs.

| Advantages | Disadvantages |

| Allows multi-material and multi-color designs | Higher mold and equipment costs |

| Enables integrated seals, grips, and decorative effects | More complex process and longer cycle times |

| High precision and strong material bonding | Requires advanced machinery and skilled operation |

| Improves both function and aesthetics in a single step | Less cost-effective for low-volume production |

Applications of Plastic Caps Across Different Industries

The molding process determines the cap’s design and properties, which in turn define its use. Different types of plastic caps serve distinct roles across industries.

Consumer Packaging

- Screw Caps – Common in beverage packaging (bottled water, carbonated drinks, juices) where accurate threading ensures tight sealing and freshness.

- Tamper-Evident Closures – Widely applied in food and pharmaceutical packaging, providing consumer safety and compliance with regulatory standards.

- Child-Resistant Caps – Essential in the pharmaceutical sector, preventing accidental ingestion of medicines.

- Flip-Top and Disc-Top Caps – Popular in personal care and cosmetics (shampoos, lotions, creams), offering convenience and controlled dispensing.

- Dispensing Caps and Pump Components – Found in cosmetics, healthcare, and household products, enabling precise dosage and improving user experience.

Industrial Packaging

- Spout Caps and Pour-Out Closures – Used in industrial chemicals and household cleaning agents such as oils, lubricants, and detergents, where durability and easy pouring are important.

- Industrial Sealing Caps and Plugs – Applied in solvent, fuel additive, and lubricant containers, designed to withstand chemical exposure and mechanical stress.

- Heavy-Duty Threaded Caps – Suitable for agricultural chemicals and construction materials, ensuring secure sealing under rough handling and transport conditions.

Choose the Right Cap Solutions for Your Packaging Needs

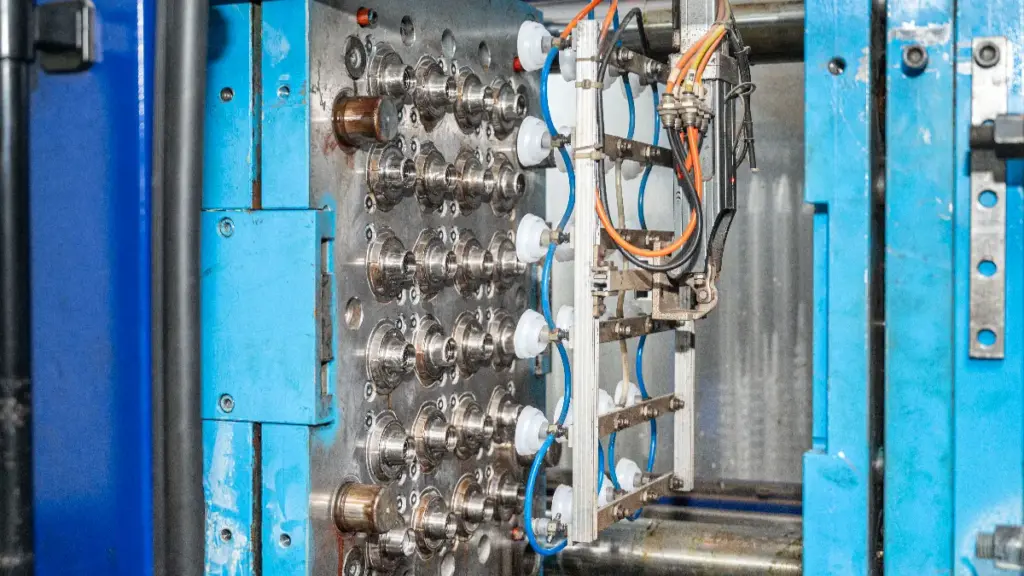

Founded in 2015, FU TEN has grown into a trusted partner in cap manufacturing. We offer more than 1,000 mold options and provide top-class molding services designed to optimize productivity and deliver packaging solutions tailored to your business needs.

Our expertise covers:

- Hot runner molds for stable performance and reduced material waste

- High-cavity mold solutions to achieve efficient, large-scale production

- Custom mold manufacturing to create caps that meet unique functional and design requirements

Contact FU TEN today to discuss your project and discover the right cap solution tailored to your packaging needs.