Una tapa de plástico industrial es un cierre funcional utilizado en envases químicos e industriales.. Se puede roscar, complemento, o a prueba de manipulaciones, diseñado para asegurar contenedores, organizar el manejo, evitar derrames durante el transporte, y servir como elemento de enmascaramiento durante procesos como recubrimiento o etiquetado. Se fabrican diferentes tipos de tapones de plástico mediante procesos de moldeo específicos., que determinan su fuerza, precisión, y usabilidad.

En las siguientes secciones, Exploraremos los principales métodos de moldeo utilizados en la producción de tapas de plástico y cómo cada uno afecta el rendimiento y la aplicación..

¿Cuál es el proceso de moldeo en la fabricación??

El moldeado es un método de fabricación que da forma al material plástico en bruto en una forma predefinida utilizando un molde.. Combina calor, presión, y, a veces, reacciones químicas para hacer que el plástico se ajuste a la cavidad del molde.. A diferencia del casting, donde el material líquido simplemente se endurece en un molde, o formando, que remodela el material mecánicamente, El moldeado garantiza dimensiones precisas., calidad constante, y la capacidad de producir formas complejas.

El proceso de moldeo también influye en las propiedades mecánicas del tapón., como la rigidez, flexibilidad, y durabilidad. Para producción de gran volumen, Se prefieren métodos de moldeo que permitan ciclos rápidos y una calidad uniforme..

Descripción general de los diferentes tipos de procesos de moldeo más comunes

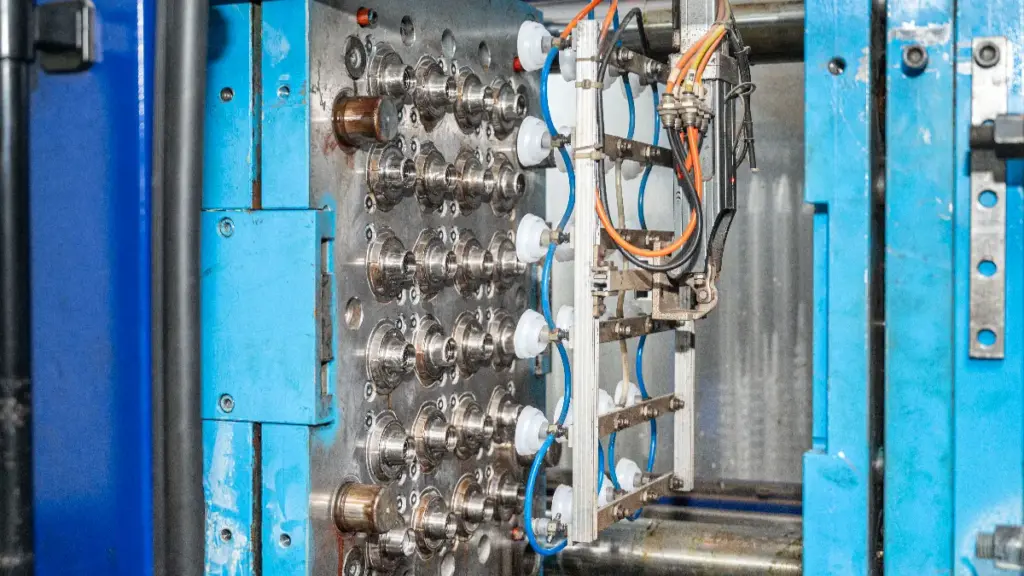

tapa de plastico La fabricación se basa en cuatro procesos principales de moldeo.: moldeo por inyección, moldeo por compresión, moldeo por soplado, y moldeado de dos o múltiples disparos.

- Moldeo por inyección es el mas comun, adecuado para alto volumen, aplicaciones de precisión.

- Moldeo por compresión Funciona bien para tapas de materiales más gruesos o especializados..

- Moldeo por soplado Es ideal para tapas huecas o de botella..

- Moldeo de dos disparos y de múltiples disparos permite combinar múltiples materiales o colores en una sola pieza.

| Proceso de moldeo | Descripción | Características clave | Limitaciones | Nivel de costo | Aplicaciones típicas |

| Moldeo por inyección | Plástico fundido inyectado en un molde de acero a alta presión.. | Alta precisión (±0,05 milímetros); tiempos de ciclo rápidos; diseños complejos posibles. | Alto coste inicial del molde; menos adecuado para piezas gruesas/huecas. | Alto coste de herramientas, bajo costo unitario a escala. | Tapones de rosca, tapas de pico, tapas a prueba de niños, cierres a prueba de manipulaciones, tapas de botellas de bebidas. |

| Moldeo por compresión | Plástico premedido prensado en la cavidad del molde calentada.. | Fuerte, partes densas; buena resistencia al calor y a los productos químicos; funciona con termoestables. | Ciclos más lentos; complejidad de diseño limitada; acabado menos suave. | Herramientas moderadas, producción más lenta. | Tapas industriales de alta resistencia, Cierres de contenedores de aceite/lubricante/disolvente.. |

| Moldeo por soplado | tubo de plástico calentado (parison) molde interior inflado para formar formas huecas. | Eficiente para tapas huecas; puede integrar caños/bisagras; tolerancias ±0,2 mm. | Menor precisión; fuerza más débil; limitado a diseños más simples. | Menor costo de herramientas, rentable para el volumen. | Tapas de pico, cierres de bebidas deportivas, tapones dispensadores. |

| Dos disparos / Moldeo por disparos múltiples | Dos o más plásticos inyectados secuencialmente en un molde.. | Combina rígido + materiales blandos; multicolor/textura; unión precisa. | Alto costo del equipo; ciclos más largos; configuración compleja. | Inversión inicial muy alta. | Gorros cosméticos premium, cierres farmacéuticos con sellos, tapas multicolores o de agarre suave. |

Moldeo por inyección

El moldeo por inyección es un proceso de fabricación preciso en el que los gránulos de plástico se calientan hasta que se funden y se inyectan en un molde de acero a alta presión.. El plástico fundido llena la cavidad del molde., tomando la forma exacta del diseño de la gorra. Una vez enfriado, el molde se abre, y la tapa terminada es expulsada. Este proceso funciona bien con termoplásticos como el polipropileno. (PÁGINAS), polietileno (educación física), y poliestireno (PD), que ofrecen buenas características de flujo, durabilidad, y resistencia al agrietamiento. Es particularmente adecuado para producción de gran volumen debido a los tiempos de ciclo rápidos y la calidad constante..

El moldeo por inyección es ideal para producir tornillo de tornillo, tapas de pico, tapas a prueba de niños, cierres a prueba de manipulaciones, y tapas de botellas de bebidas estándar. El método permite que características detalladas, como nervaduras internas, aumenten la resistencia estructural sin agregar material adicional.. Las tolerancias pueden ser tan estrictas como ±0,05 mm., Garantizar que las tapas se ajusten a las botellas con precisión y funcionen de manera confiable en aplicaciones de sellado..

| Ventajas | Desventajas |

| Alta precisión y tolerancias estrictas (±0,05 milímetros) | Alto coste inicial del molde ($5,000–$50,000) |

| Producción rápida adecuada para tiradas de gran volumen | Menos adecuado para tapas muy gruesas o huecas |

| Capacidad para producir diseños complejos y características detalladas. | Requiere un control cuidadoso del material y la temperatura. |

| Calidad y repetibilidad constantes | Flexibilidad limitada para diseños de múltiples materiales o colores. |

Moldeo por compresión

El moldeo por compresión implica colocar una cantidad previamente medida de plástico en un recipiente abierto., cavidad del molde calentada. Luego se cierra el molde., y la presión obliga al plástico a adaptarse a la forma de la cavidad.. Después de enfriar, se quita la tapa. Este método funciona particularmente bien con plásticos termoestables como fenólicos o melamina., que son difíciles de procesar mediante moldeo por inyección.

El moldeo por compresión es ideal para producir espesores, Tapas resistentes para contenedores industriales y químicos., como el petróleo, lubricante, y cierres de botellas de disolventes, donde la durabilidad y la resistencia al calor, químicos, y el impacto son esenciales. Las tolerancias suelen ser de alrededor de ±0,1 mm., ligeramente más grande que el moldeo por inyección pero suficiente para uso industrial. También es compatible con diseños de gorras más simples que no requieren hilos muy detallados ni logotipos complejos..

| Ventajas | Desventajas |

| Produce espesor, fuerte, y tapas duraderas | Tiempos de ciclo más lentos que el moldeo por inyección |

| Adecuado para plásticos termoestables y aplicaciones de alta temperatura. | Complejidad de diseño y detalle de superficie limitados. |

| Excelente resistencia química y al calor. | Menores volúmenes de producción |

| Rendimiento confiable para aplicaciones industriales | Requiere medición y prensado precisos del material. |

Moldeo por soplado

El moldeo por soplado es un proceso de fabricación en el que el plástico calentado se infla con aire dentro de la cavidad de un molde para formar formas huecas.. El proceso comienza con un parisón o preforma. (un tubo de plástico calentado) siendo colocado en el molde. Luego se introduce aire comprimido., expandir el plástico contra las paredes del molde para crear la forma deseada. Una vez enfriado, el molde se abre, y se retira el producto terminado. Esta técnica funciona especialmente bien con polietileno. (educación física) y tereftalato de polietileno (MASCOTA).

El moldeo por soplado se utiliza principalmente para fabricar artículos de plástico huecos, como botellas., paso, y contenedores, incluyendo tapas con picos integrales o cierres con bisagras. Si bien el proceso permite diseños funcionales, Es menos preciso que el moldeo por inyección.. Las tolerancias típicas son de alrededor de ±0,2 mm., que es suficiente para tapones sin rosca o funciones de dispensación simples, pero menos adecuado para cierres de alta precisión.

| Ventajas | Desventajas |

| Eficiente para diseños de tapas huecas o livianas | Menor precisión en comparación con el moldeo por inyección |

| Rentable para botellas y contenedores grandes | Limitado a geometrías de tapa más simples |

| Costo de herramientas relativamente bajo | Los detalles de la superficie y los hilos son menos precisos. |

| Puede producir caños integrados o piezas con bisagras. | Resistencia estructural más débil que el moldeo por inyección/compresión |

Moldeo de dos disparos y de múltiples disparos

dos tiros (o multidisparo) El moldeado es un proceso avanzado en el que se inyectan dos o más plásticos diferentes en el mismo molde en pasos secuenciales., creando una única parte integrada. Este método permite la combinación de diferentes colores., texturas, o propiedades del material en una sola tapa. Por ejemplo, Se puede moldear un cuerpo rígido de polipropileno junto con un elastómero termoplástico blando. (TPE) Forro para mejorar el agarre y el sellado..

Esta técnica se utiliza comúnmente en envases premium., farmacéuticos, y productos de cuidado personal donde tanto la funcionalidad como el atractivo visual son importantes. Tapas con empuñaduras suaves al tacto., marca multicolor, o los sellos incorporados a menudo se fabrican utilizando moldeo de dos disparos. Las tolerancias suelen ser similares a las del moldeo por inyección estándar., alrededor de ±0,05–0,08 mm, asegurando un rendimiento de sellado confiable al tiempo que permite diseños complejos.

| Ventajas | Desventajas |

| Permite diseños multimaterial y multicolor. | Mayores costos de moldes y equipos. |

| Permite sellos integrados, apretones, y efectos decorativos | Proceso más complejo y tiempos de ciclo más largos |

| Unión de materiales fuerte y de alta precisión | Requiere maquinaria avanzada y operación calificada. |

| Mejora tanto la función como la estética en un solo paso. | Menos rentable para la producción de bajo volumen |

Aplicaciones de las tapas de plástico Al otro lado de Diferente Industrias

El proceso de moldeo determina el diseño y las propiedades de la tapa., que a su vez definen su uso. Los diferentes tipos de tapas de plástico cumplen funciones distintas en todas las industrias.

Embalaje de consumo

- Tornillo de tornillo – Común en envases de bebidas. (agua embotellada, bebidas carbonatadas, jugos) donde el roscado preciso garantiza un sellado hermético y frescura.

- Cierres de manipulación – Ampliamente aplicado en envases alimentarios y farmacéuticos., Proporcionar seguridad al consumidor y cumplimiento de las normas reglamentarias..

- Tapas a prueba de niños – Imprescindible en el sector farmacéutico, prevenir la ingestión accidental de medicamentos.

- Tapas abatibles y con tapa de disco – Popular en cuidado personal y cosmética. (champús, lociones, cremas), Ofreciendo comodidad y dispensación controlada..

- Tapas dispensadoras y componentes de la bomba – Se encuentra en cosméticos., cuidado de la salud, y productos para el hogar, permitiendo una dosificación precisa y mejorando la experiencia del usuario.

Embalajes industriales

- Tapas de pico y cierres de vertido – Utilizado en iProductos químicos industriales y agentes de limpieza domésticos como aceites., lubricantes, y detergentes, donde la durabilidad y la facilidad de vertido son importantes.

- Tapones y tapas de sellado industriales – Aplicado en solvente, aditivo de combustible, y contenedores de lubricante, Diseñado para resistir la exposición química y el estrés mecánico..

- Tapas roscadas de alta resistencia – Adecuado para productos químicos agrícolas y materiales de construcción., Garantizar un sellado seguro en condiciones duras de manipulación y transporte..

Elija las soluciones de tapa adecuadas para sus necesidades de embalaje

Fundada en 2015, FU DIEZ se ha convertido en un socio confiable en la fabricación de gorras. Ofrecemos más de 1,000 opciones de moldes y proporcionar servicios de moldeo de primera clase diseñados para optimizar la productividad y ofrecer soluciones de embalaje adaptadas a las necesidades de su negocio..

Nuestra experiencia cubre:

- Moldes de canal caliente para un rendimiento estable y una reducción del desperdicio de material

- Soluciones de moldes de alta cavidad para lograr eficiencia, producción a gran escala

- Fabricación de moldes personalizados para crear tapas que cumplan requisitos funcionales y de diseño únicos

Póngase en contacto con FU TEN hoy para discutir su proyecto y descubrir la solución de tapa adecuada adaptada a sus necesidades de embalaje.