One-Stop Solution

We Understand Your Daily Challenges

You have to coordinate separate suppliers for cans, कैप्स, molds and shipping – communication is slow and it is hard to know who is responsible when something goes wrong.

Caps and can openings do not perfectly match, causing line stoppages, torque problems and leakage during transport.

Each packaging closure supplier provides different drawings and documents, making it difficult for your quality and regulatory teams to complete audits and approvals on time.

New projects require repeated sampling and testing, but no one is looking at the full system from can, closure and filling line together.

You need packaging partners who can support different export requirements and certificates, but most suppliers only focus on production and leave logistics and documentation to you.

How FUTEN’s One-Stop Solution Helps You

Fewer suppliers, clearer responsibility

Better performance and compatibility

Faster approvals and smoother launches

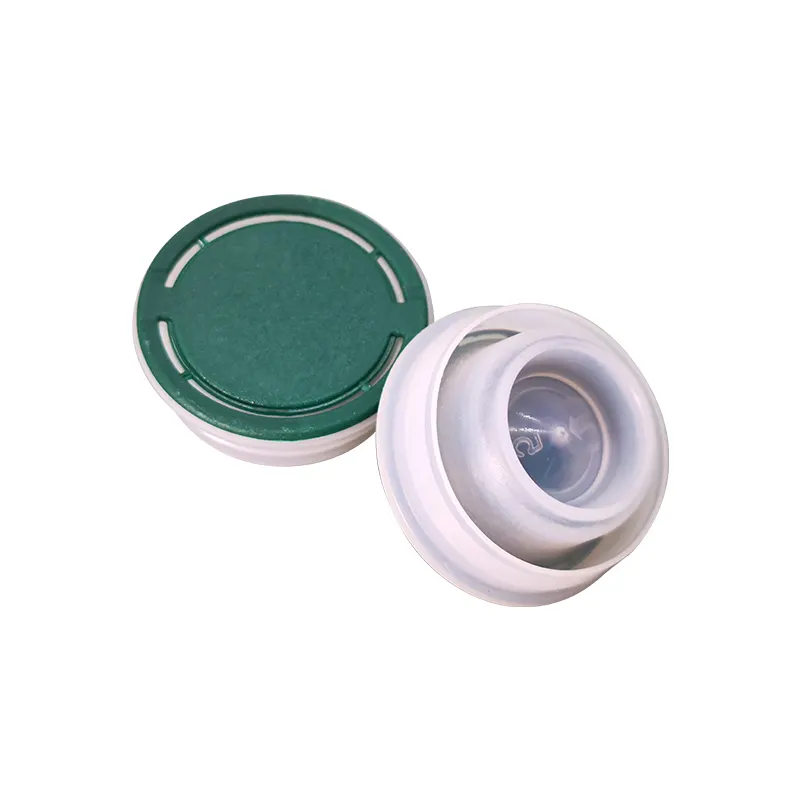

Different Metal and Plastic Closures You Can Choose

What You Get with Our One-Stop Service

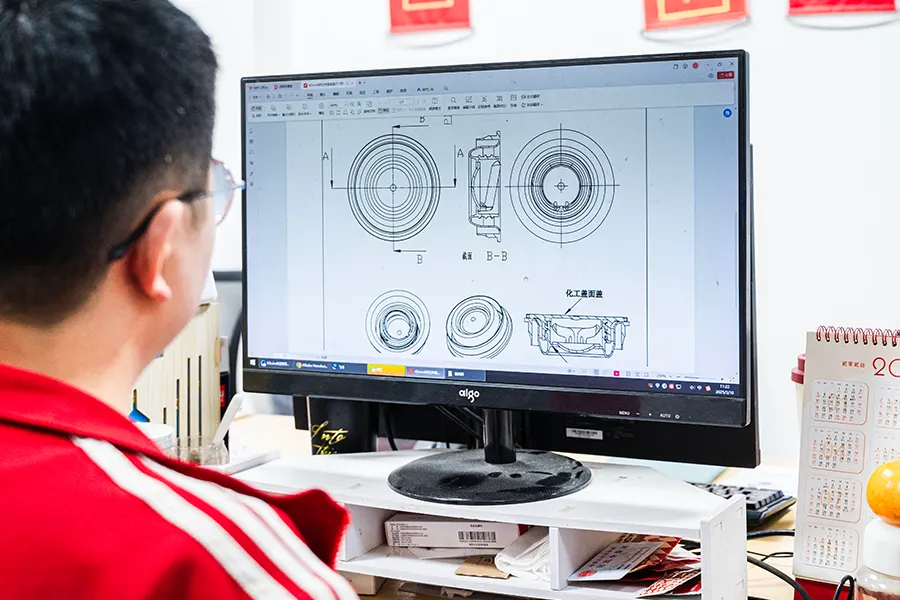

Design & Engineering

- Joint review of your current or planned cans, closures and filling line parameters.

- Recommendations for can shapes, opening sizes and closure types that fit your product, viscosity and markets.

- Detailed 2D/3D drawings and material specifications for your engineering and quality teams.

Sampling & Validation

- Rapid sampling of matched cans and closures for line trials and transport tests.

- Fine-tuning of neck finish, torque, liners and inserts based on your test feedback.

- Support for pilot runs so your production team can validate real operating conditions.

Mass Production & गुणवत्ता आश्वासन

- In-house molding and production with 70+ new-generation machines and fully automated assembly.

- 280M+ annual closure capacity and scalable can production for long-term, high-volume projects.

- Four-phase quality control including pressure and tightness tests, with 100% inspection using automated visual systems.

- Use of all-new Sinopec materials for consistent performance, especially in critical applications.

Logistics & Documentation

- Dedicated shipping team coordinating sea freight and local transport from our Guangzhou hub.

- Complete export documentation including SGS and ISO certificates, CO, फॉर्म ई, FORM K and other region-specific requirements.

- Experience supporting customers in the Middle East, Africa, दक्षिण अमेरिका, USA and Asia, helping your internal teams clear compliance faster.

Simple 5-Step to Complete Your Metal and Plastic Caps Order

Step 1 – Share Your Packaging Brief

Tell us about your product, existing or planned cans and closures, filling line setup, annual volumes and key markets. We use this information to understand your constraints and priorities before suggesting any options.

Step 2 – Get a Technical Review & Proposal

Our engineering team reviews your current packaging and line conditions and then proposes matched can-and-closure combinations. You receive initial drawings, technical notes and a commercial quotation to discuss internally.

Step 3 – Test Samples on Your Line

We produce sample cans and closures for you to run on your filling line and simulate transport conditions. Your feedback on leakage, torque and handling helps us fine-tune dimensions, inserts and materials where necessary.

Step 4 – Confirm Specifications and Start Production

Once samples are approved, we lock all specifications, agree on packaging details and set delivery schedules. Mass production then starts in our automated facility with full quality control at each stage.

Step 5 – Receive Stable Supply and Ongoing Support

Our logistics team arranges shipment and export documents, while your dedicated contact monitors orders. We stay available to support future volume changes, packaging upgrades or new projects in the same one-stop model.

पूछे जाने वाले प्रश्न

क्या आप एक कारखाने या ट्रेडिंग कंपनी हैं?

हम Zengcheng Guangzhou शहर में स्थित एक कारखाना हैं, हमारे कारखाने में आपका स्वागत है.

मुफ्त नमूने कैसे प्राप्त करें?

मुक्त नमूने के लिए , आपको केवल माल ढुलाई की लागत वहन करने की आवश्यकता है.

आपका MOQ और डिलीवरी का समय क्या है ?

हम कम मात्रा को स्वीकार करते हैं, अगर हमारे पास स्टॉक है ,डिलीवरी का समय है 5 10 दिनों तक, यदि कोई स्टॉक नहीं है, आपकी मात्रा पर निर्भर करता है , यह 15 25 दिन तक.

अपने उत्पाद के लिए उच्च गुणवत्ता कैसे रखें?

सभी उत्पाद को हमारी पूर्ण स्वचालित मशीन के माध्यम से एक -एक करके निरीक्षण किया जाएगा.

आपका फायदा क्या है?

डिलीवरी त्वरित, कारखाना मूल्य, व्यापार आश्वासन सुरक्षित, SGS प्रमाणपत्र पारित किया, व्यावसायिक दस्तावेज सेवा, समय पर समस्या हैंडलिंग.

क्या आप डिलीवरी से पहले अपने सभी सामानों का परीक्षण करते हैं?

हाँ, हम आचरण करते हैं 100% स्वचालित मशीन को सील करके डिलीवरी से पहले परीक्षण करें.